Essential Maintenance Practices for Air Circuit Breakers

Air circuit breakers are crucial for protecting electrical systems, yet many neglect their maintenance. Regular upkeep can prevent costly breakdowns and ensure safety. This blog post will outline essential maintenance practices, safe handling techniques, and the importance of documentation for air circuit breakers. By understanding these practices, readers will learn how to enhance the reliability of their electrical systems and address potential issues before they escalate. Engaging with this content will equip readers with the knowledge to maintain their air circuit breakers effectively, protecting both their property and investments.

Essential Maintenance Practices for Air Circuit Breakers

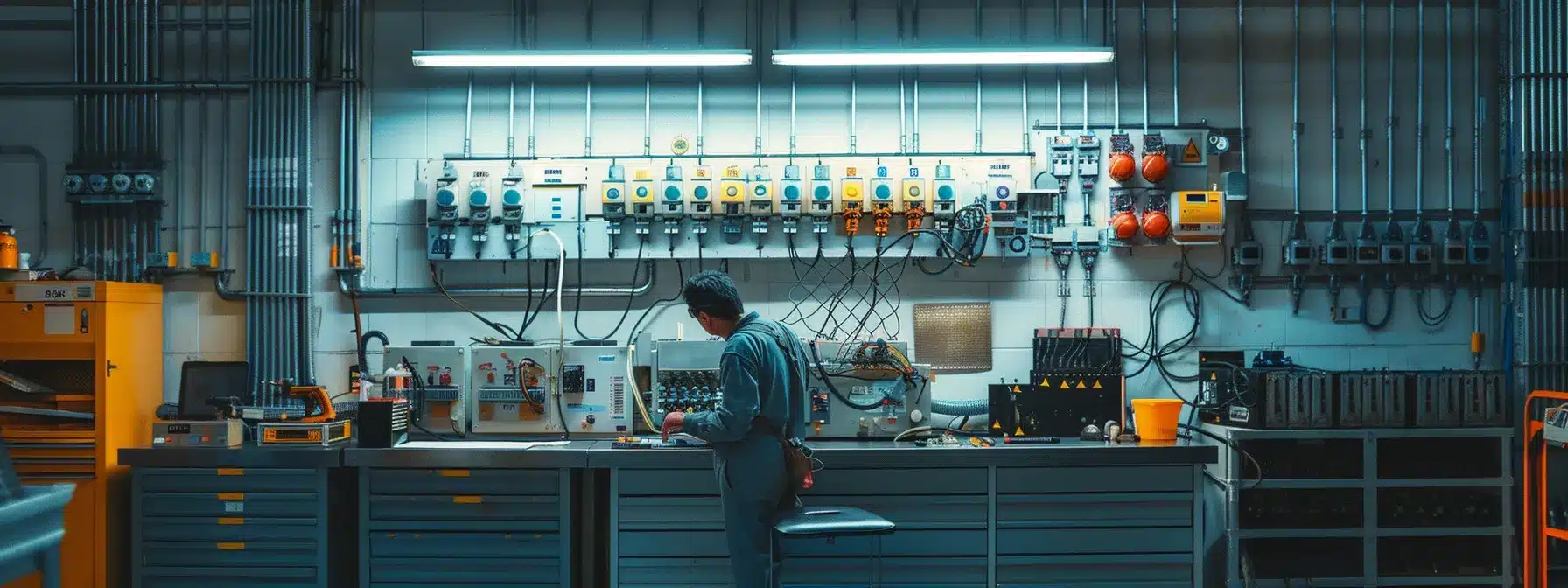

Regular inspections of air circuit breakers are essential to ensure safety and reliability in electrical systems. Key cleaning techniques, alongside understanding the functionality of the air system, contribute to optimal performance. Essential testing protocols help identify issues, while common faults and troubleshooting tips provide guidance for efficient circuit breaker repair. This section covers these critical aspects to maintain effective electrical devices.

Importance of Regular Inspections for Air Circuit Breakers

Regular inspections of air circuit breakers play a vital role in maintaining electronics and reducing the risk of failures in electrical systems. These inspections ensure that the compressed air used in the breakers is effectively managed, allowing for optimal circuit breaker performance and energy efficiency. By detecting potential issues early, professionals can address them proactively, thereby enhancing overall system reliability and safety.

Key Cleaning Techniques for Optimal Performance

Key cleaning techniques for air circuit breakers are crucial to ensure optimal performance and longevity. Electrical engineers recommend implementing a regular checklist that includes visual inspections for dust accumulation, corrosion, or any signs of wear. Additionally, managing heat levels and ensuring that the power supply remains stable can prevent overheating, ultimately safeguarding the integrity of the circuit breaker system.

Understanding the Functionality of the Air System

Understanding the functionality of the air system within air circuit breakers is crucial for preventing hazards related to overcurrent and system failures. Electricians emphasize the importance of efficient air distribution as it assists in proper breaker operation, allowing them to handle ground faults effectively. By ensuring that the air components are maintained and functioning correctly, professionals can mitigate the risk of electrical failures, ultimately enhancing the safety and reliability of the electrical system.

Essential Testing Protocols for Air Circuit Breakers

Essential testing protocols for air circuit breakers are crucial for ensuring the reliability of switchgear and minimizing downtime. Professionals recommend regularly measuring contact resistance to identify any potential issues that could interfere with the flow of electric current. Using a vacuum cleaner to remove dust and debris from the breaker components can also enhance performance, as clean components reduce the likelihood of overheating and electrical failures.

Common Faults and Troubleshooting Tips

Common faults in air circuit breakers often stem from issues such as short circuits or insufficient dielectric strength, which can impair the delivery of electric power. Technicians emphasize the importance of regular maintenance checks to identify problems early, particularly in substations where these devices are crucial for managing electrical loads. By applying appropriate troubleshooting tips, such as verifying connections and performing routine testing, professionals can enhance the reliability of air circuit breakers and maintain operational efficiency.

Safe Handling and Operation of Air Circuit Breakers

Proper training for personnel on air circuit breaker (ACB) usage is essential for maintaining safety and efficiency. Wearing appropriate safety gear and following precautions can prevent accidents. Implementing lockout/tagout procedures ensures that maintenance is performed safely. Understanding the electrical system compatibility is critical to effective operation. Each of these topics highlights preventive maintenance strategies and the importance of attention to detail, particularly in environments like the United Arab Emirates where dirt and oil can accumulate quickly.

Proper Training for Personnel on ACB Usage

Proper training for personnel on air circuit breaker (ACB) usage is critical for ensuring safety and efficient operations. Technicians must understand the importance of regular inspection practices as well as wearing appropriate safety gear to mitigate risks during maintenance tasks. Training should also emphasize the function of relays in circuit breaker maintenance, ensuring that personnel can quickly identify issues and respond effectively to prevent hazards.

Importance of Safety Gear and Precautions

The importance of safety gear and precautions in handling air circuit breakers cannot be overstated. Proper protective equipment, such as gloves and goggles, shields technicians from potential hazards like dust and contamination, which can lead to corrosion and functional failures in electrical systems. Additionally, adherence to occupational safety and health standards ensures that all maintenance procedures are performed safely, minimizing risks and promoting a secure working environment.

Implementing Lockout/Tagout Procedures

Implementing lockout/tagout procedures is a critical practice for safely maintaining air circuit breakers. This process ensures that electrical circuits are properly shut down and secured before any maintenance work begins, preventing accidental energization. Technicians should familiarize themselves with these procedures to safeguard against potential hazards, as they provide a clear protocol for isolating energy sources and confirming that equipment is de-energized, thereby enhancing safety and operational efficiency.

Understanding the Electrical System Compatibility

Understanding electrical system compatibility is crucial for the effective operation of air circuit breakers. Ensuring that the specifications of the circuit breakers align with the overall electrical infrastructure prevents performance issues and potential failures. Electricians must assess factors such as voltage ratings, current capacity, and system configuration to guarantee seamless integration, thereby enhancing the reliability of the electrical system.

Upgrading and Retrofitting Air Circuit Breakers

Evaluating when to upgrade current air circuit breaker systems is essential for optimal performance and reliability. Retrofitting offers significant benefits, enhancing the functionality and safety of existing setups. Selecting the right components for upgrades ensures compatibility and efficiency. Conducting performance assessments post-upgrade further confirms the improvements made, solidifying the operational integrity of the electrical system.

Evaluating When to Upgrade Current Systems

Determining when to upgrade current air circuit breaker systems is essential for maintaining optimal performance and ensuring safety. Factors such as the age of the equipment, changing electrical loads, and advancements in technology should be evaluated to assess the need for upgrades. For example, outdated breakers may not handle increasing power demands effectively, leading to potential failures that can disrupt operations and compromise safety in both residential and commercial environments.

Benefits of Retrofitting for Enhanced Reliability

Retrofitting air circuit breakers significantly enhances reliability by integrating modern technology and improved components into existing systems. This process not only boosts the performance of older setups but also aligns them with new safety standards, which is essential for preventing electrical failures. By adopting retrofitting strategies, organizations ensure their electrical systems can handle evolving demands while maintaining operational integrity and safety.

Selecting the Right Components for Upgrades

Selecting the right components for upgrades is essential in enhancing the performance of air circuit breakers. Professionals should assess the specific needs of their electrical systems, focusing on factors such as voltage requirements and current ratings. By choosing components that align with modern safety standards, operators can significantly improve system reliability and efficiency, ultimately reducing the risk of operational disruptions.

Conducting Performance Assessments Post-Upgrade

Conducting performance assessments post-upgrade of air circuit breakers is essential to ensure enhanced reliability and safety within electrical systems. Technicians should focus on evaluating key metrics such as operational efficiency and response times to overload conditions. By implementing these assessments, professionals can verify that upgraded components are functioning as intended, thereby minimizing the risk of system failures and ensuring uninterrupted power delivery in both residential and commercial settings.

Documentation and Record-Keeping for Air Circuit Breakers

Maintaining detailed maintenance logs is crucial for accountability in air circuit breaker management. A comprehensive service history serves as a valuable reference for future repairs and performance assessments. Utilizing digital tools streamlines record management, while creating a consistent maintenance schedule ensures routine evaluations. Together, these practices enhance the reliability and safety of electrical systems.

Maintaining Maintenance Logs for Accountability

Maintaining detailed maintenance logs for air circuit breakers is essential for ensuring accountability and system integrity. By documenting each inspection, repair, or upgrade, technicians create a valuable reference that helps track the history and performance of the equipment. This proactive approach not only aids in identifying patterns or recurring issues but also ensures adherence to regulatory standards, ultimately enhancing the reliability and safety of electrical systems.

Importance of Service History for Future Reference

The service history of air circuit breakers is crucial for ensuring informed maintenance and operational decisions. A well-documented record allows technicians to identify trends in performance, recognize recurring issues, and predict potential failures. By maintaining a detailed service history, professionals also ensure compliance with regulatory standards, ultimately enhancing the reliability and safety of electrical systems.

Utilizing Digital Tools for Effective Record Management

Utilizing digital tools for effective record management enhances the maintenance of air circuit breakers. These tools facilitate the collection and organization of maintenance logs, making it easier for technicians to track service history, inspections, and repairs. By implementing software solutions, organizations can efficiently analyze data trends, identify recurring issues, and ensure compliance with safety standards, ultimately contributing to the reliability and performance of electrical systems.

Creating a Maintenance Schedule to Ensure Consistency

Creating a maintenance schedule for air circuit breakers is fundamental for ensuring long-term reliability and performance. Electrical professionals recommend setting specific intervals for inspections, cleaning, and testing, tailored to the usage and environment of the breakers. This structured approach not only helps track maintenance progress but also proactively addresses potential issues before they escalate, significantly reducing the risk of costly downtime.

Evaluating Air Circuit Breaker Performance

Identifying key performance indicators is essential for assessing the effectiveness of air circuit breakers. Conducting regular performance tests provides valuable insights into their operational reliability. Analyzing data from these tests helps professionals drive improvements while adjusting maintenance practices based on performance insights ensures optimal functionality. Together, these strategies contribute to enhanced safety and efficiency in electrical systems.

Identifying Key Performance Indicators

Identifying key performance indicators (KPIs) for air circuit breakers is vital for assessing their operational efficiency. Monitoring metrics such as trip time, current carrying capacity, and the frequency of maintenance issues allows professionals to evaluate the effectiveness of these devices. By focusing on these KPIs, technicians can proactively address potential concerns, ensuring reliable performance and minimizing the risk of breakdowns in electrical systems.

Conducting Performance Tests Regularly

Conducting performance tests regularly is essential for maintaining the reliability of air circuit breakers. These tests help verify the effectiveness of the breakers and ensure they are responding accurately to overloads and faults. By measuring key metrics such as trip time and operational efficiency, technicians can identify potential issues early and take corrective measures to avoid power disruptions, ultimately enhancing the safety and functionality of the electrical system.

Analyzing Data to Drive Improvement

Analyzing performance data from air circuit breakers is a critical step in enhancing their reliability and operational efficiency. By reviewing key metrics such as trip times and maintenance frequencies, professionals can pinpoint areas for improvement and implement necessary adjustments. For example, if data indicates frequent trips during specific loads, technicians can investigate the system’s capacity and performance, allowing them to take proactive measures to address these issues before they lead to failures.

Adjusting Maintenance Practices Based on Performance Insights

Adjusting maintenance practices based on performance insights is a fundamental approach for ensuring the reliability of air circuit breakers. By analyzing key indicators, such as trip times and the frequency of maintenance issues, technicians can identify specific areas that require immediate attention. For instance, if frequent trips are noted during high loads, this may indicate the need for component upgrades or adjustments in the operational setup, ultimately enhancing the overall efficiency and safety of the electrical system.

Understanding Regulatory Compliance for Air Circuit Breakers

Overview of relevant industry standards is essential for maintaining air circuit breakers and ensuring compliance with electrical safety regulations. Staying current with these regulations is critical, as consequences of non-compliance can include significant safety risks and operational inefficiencies. Engaging with regulatory bodies provides valuable guidance, reinforcing best practices in maintenance and supporting the reliability of electrical systems.

Overview of Relevant Industry Standards

Compliance with relevant industry standards is crucial for the effective maintenance and operation of air circuit breakers. Standards set by organizations such as the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC) provide guidelines that ensure safety and reliability in electrical systems. Adhering to these standards not only helps in maintaining operational integrity but also reduces the risk of failures, supporting overall system performance in both residential and commercial settings.

Staying Current With Electrical Safety Regulations

Staying current with electrical safety regulations is vital for ensuring the safe operation of air circuit breakers. Professionals must regularly review guidelines provided by organizations like NEMA and IEC to identify any updates that affect maintenance practices. By adhering to these regulations, technicians can mitigate the risks associated with non-compliance, thereby enhancing the reliability and safety of electrical systems in both residential and commercial environments.

Consequences of Non-Compliance in Maintenance Practices

Non-compliance in maintenance practices for air circuit breakers can lead to severe consequences, including safety hazards and significant operational inefficiencies. Deterioration of equipment due to inadequate inspections and servicing may increase the likelihood of failures, posing risks to both personnel and property. Additionally, organizations may face regulatory penalties, which can strain financial resources and undermine credibility in both residential and commercial environments.

Engaging With Regulatory Bodies for Guidance

Engaging with regulatory bodies is essential for ensuring compliance with standards in air circuit breaker maintenance. Professionals should actively seek guidance from organizations such as the National Electrical Manufacturers Association (NEMA) or the International Electrotechnical Commission (IEC) to stay updated on best practices and regulatory requirements. By maintaining a clear line of communication with these bodies, technicians can effectively address compliance challenges and enhance the safety and reliability of their electrical systems.

Conclusion

Essential maintenance practices for air circuit breakers are critical to ensuring safety, reliability, and optimal performance in electrical systems. Regular inspections and cleaning help identify potential issues early, reducing downtime and enhancing efficiency. Proper training, compliance with safety regulations, and utilizing modern components further contribute to the longevity and functionality of circuit breakers. Prioritizing these practices safeguards both personnel and property, making them indispensable for maintaining robust electrical operations.